Architectural Applications of Aluminum Panels

Ventilated Facades and Energy Efficiency

Ventilated facades have become pretty much standard in contemporary building design these days, especially when it comes to those sleek aluminum panel systems. The way they work is actually quite clever - there's this gap created between the outer layer of the building and the actual structure underneath, which acts like an insulating buffer zone. This little space makes a big difference in cutting down on energy bills because it stops heat from escaping so easily. Energy watchdog groups have tracked some impressive stats showing buildings with these systems can save anywhere from 20% to 40% on their heating costs alone. Take the YPF Vaca Muerta project for example. When they installed those aluminum ventilated panels across the entire facade, maintenance crews noticed something interesting happening during winter months. The indoor temperatures stayed more stable without needing constant adjustments to the HVAC system, and over time, the building just seemed to handle extreme weather conditions better than similar structures without this kind of insulation.

Cladding Systems for Modern Structures

Aluminum panels are becoming a staple in today's building cladding systems because they look great and stand up to whatever Mother Nature throws at them. The smooth finish really makes modern buildings pop visually, but there's more to it than just looks these panels actually protect against rain, wind, and sun damage. Architects and builders keep pointing out how much aluminum is taking over construction sites lately. Take a walk through any mall or business district and chances are good you'll see aluminum cladding on display. These buildings last longer too since the material resists wear and tear better than many alternatives. Shopping centers especially seem to favor this stuff, probably because it maintains its appearance for years without needing constant maintenance or replacement.

Insulation and Weatherproofing Solutions

Aluminum panels work really well as insulation and protection from the weather, making buildings much more durable overall. The thermal properties of these panels give them an edge that most traditional building materials just can't keep up with. Research shows that buildings using aluminum tend to save on heating bills because they handle temperature changes better. When builders opt for aluminum instead of standard materials, their structures stay protected from harsh weather while keeping indoor temperatures steady. This choice also cuts down on maintenance expenses in the long run, which is why more construction professionals are turning to aluminum solutions these days.

Design Versatility in Modern Construction

Aesthetic Flexibility for Commercial and Residential Projects

Aluminum panels have serious visual appeal that's hard to ignore, adapting beautifully to all sorts of architectural styles in both commercial buildings and homes. Architects love working with them because they just seem to fit right into whatever design scheme someone wants. Looking at what's happening in the market these days, more people are choosing aluminum for their projects thanks to that clean, modern appearance and how versatile it really is. Take those shiny new office buildings downtown with their smooth metal exteriors, or think about homeowners who've completely transformed their spaces with custom aluminum accents. The material works wonders whether we're talking about restoring old brick buildings or creating cutting edge structures from scratch. What makes aluminum so special is this incredible balance between form and function that meets almost every design need out there.

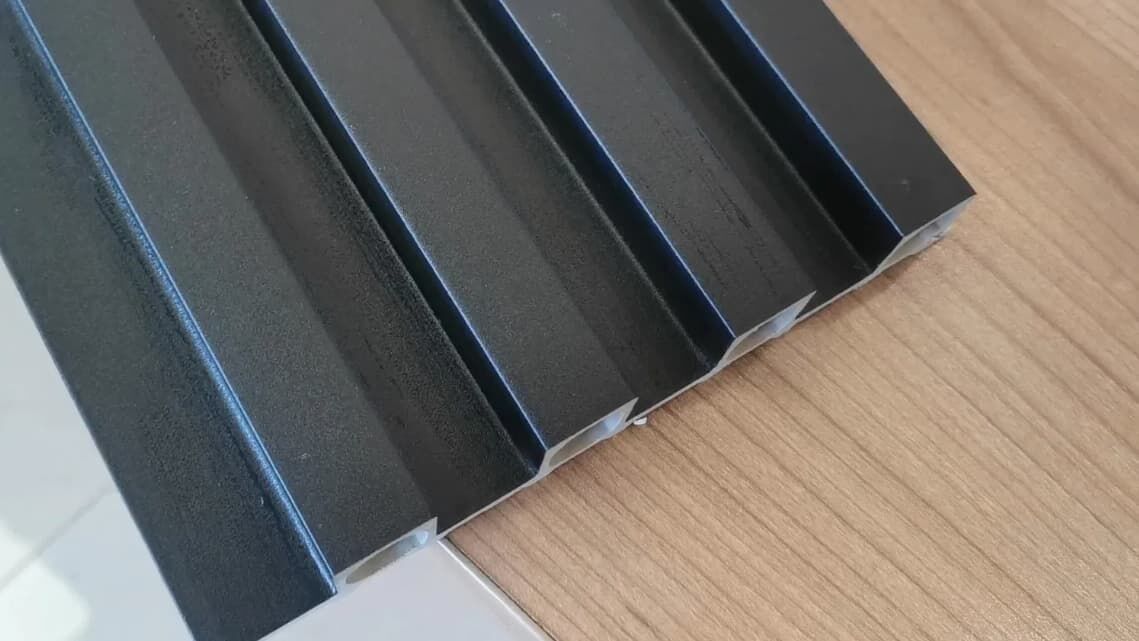

Customization Options: Colors, Textures, and Finishes

Aluminum panels really stand out when it comes to customization options. They come in all sorts of colors, textures and finishes that match what modern buildings need these days. People seem to want something different these days too, not just standard looks anymore. The ability to customize makes a big difference for architects wanting to create something special. Customization helps push boundaries creatively while making sure buildings fit into their surroundings culturally and environmentally. Aluminum gives designers so many choices actually – think shiny metal surfaces next to duller matte ones – which means they can bring their ideas to life exactly how they envision them without compromise.

Mid-Century Modern Revival in Contemporary Design

Mid-century modern design is making a comeback, and aluminum panels are at the heart of connecting old school style with what's happening now in architecture. These metal panels bring those signature clean lines and simple shapes from the mid-century era right into today's building projects. Look around at design shows and galleries, and you'll see aluminum doing its thing pretty well. It lasts forever and looks great too, which fits perfectly with that mid-century vibe people love so much. Architects have been showing off this trend lately at exhibitions across the country. They're proving how aluminum panels can mix the warm nostalgia of the past with modern touches, giving spaces that special something that feels both fresh and familiar all at once.

Sustainability and Environmental Benefits

Recyclability and Eco-Friendly Manufacturing

Aluminum panels bring real green benefits because they recycle so well and come from manufacturing processes that are pretty good for the environment. The thing about aluminum is it keeps going strong even after being recycled many times. Around 70 percent of all the aluminum ever dug out of the ground remains in circulation somewhere right now. That kind of reuse cycle makes aluminum stand out among sustainable building materials. Manufacturers have also made some progress lately in cutting down on waste during production while using less energy overall. Recycling groups back this up too, showing aluminum beats most other materials when looking at its whole life cycle from creation to disposal. We should definitely take notice of how far aluminum has come in becoming more environmentally responsible as part of our larger push toward greener construction practices.

Thermal Efficiency and Energy Savings

Aluminum panels bring real advantages when it comes to keeping buildings cool or warm, which saves money on energy bills over time. The material works great as insulation because it helps keep indoor temps stable without needing so much heating or air conditioning. That means less strain on HVAC systems and lower monthly costs for property owners. Aluminum also reflects sunlight pretty well and doesn't get damaged easily from UV exposure, so buildings stay looking good while performing better thermally. Research shows buildings with aluminum exteriors tend to use around 15-20% less energy than those without. Take beachfront homes for instance many builders now specify aluminum panels there since they handle both scorching summer days and chilly winter nights without warping or fading. Makes sense really, considering how harsh saltwater air can be on regular materials.

Reducing Carbon Footprint with Lightweight Materials

Aluminum panels are pretty light compared to other building materials, and this actually makes a big difference when it comes to cutting down on carbon emissions during construction. When builders use aluminum instead of heavier options, they need less fuel for transporting materials to sites and spend fewer resources installing them too. Take steel as an example aluminum weighs about two thirds less, so there's just naturally less impact on the environment over time. Environmental researchers have looked at different construction materials and keep finding similar results aluminum stands out for being greener. Construction companies that switch to aluminum where possible aren't just saving money on logistics costs they're also making their projects more sustainable overall.

Safety and Durability Considerations

Fire-Resistant Core Materials and Building Codes

Fire resistant materials in aluminum panels really matter when it comes to meeting those safety standards everyone has to follow. The panels typically have cores filled with stuff like mineral based compounds that make them much safer overall. Building codes around fire safety are pretty strict these days too. Many require materials that either stop fires completely or at least slow them down before they spread throughout a structure. When builders install aluminum panels with those fire resistant cores inside, they get all sorts of compliance advantages. Fire safety groups have actually tracked this stuff over time and found fewer incidents in buildings where such materials were used during construction. Makes sense really why so many architects specify these panels now for commercial projects especially.

Long-Term Performance in Harsh Conditions

Aluminum panels stand up really well to wear and tear, holding their own in all sorts of weather conditions from heavy storms to scorching sun exposure. They resist rust and corrosion pretty effectively too, so they keep protecting whatever surface they're installed on despite constant exposure to rain, strong winds, and UV rays. Real world testing shows these panels don't lose their strength after years of use either. Most major producers back this up with warranty periods lasting anywhere between 10 to 25 years, which speaks volumes about how confident they are in their product quality. Because of this track record, many architects and builders specify aluminum when designing structures meant to last decades in tough climates where regular materials would fail much sooner.

Aluminum Panels vs. Traditional Building Materials

Cost-Effectiveness Compared to Steel and Concrete

In construction circles, switching to aluminum panels instead of old school materials like steel and concrete saves money in ways most people don't realize at first glance. The upfront price tag looks good, sure, but what really matters is how these panels keep cutting costs year after year. Their lightweight nature means installers don't need massive support structures or extra manpower during setup. Think about it this way: a recent commercial project saved around $150,000 just by going with aluminum instead of steel panels. And let's talk about what happens down the road. Aluminum doesn't rust or degrade like steel does, so there's no ongoing maintenance headache. Contractors know this stuff lasts decades with minimal fuss while steel requires constant sealing and repairs. When builders factor in all those hidden costs over time, aluminum panels start looking like one of the smartest investments they can make on any job site today.

Weight Advantages Over Stone and Brick

Aluminum panels stand out because they're so much lighter than old school materials like stone and brick. The lighter weight puts less strain on buildings, making it easier to plan and install them without needing massive support structures. When architects work with these panels instead of heavy bricks or stones, they get way more freedom in how they design spaces. Installation goes quicker too, which cuts down on those costly labor bills. Shipping is another area where money gets saved big time since lighter panels need less fuel during transport and take up less space in delivery trucks. Contractors love this aspect especially when working on large projects across multiple sites. The whole industry has started seeing new possibilities emerge from this weight benefit, leading to creative solutions that would have been impossible with heavier materials just a few years ago.

Low Maintenance vs. Wood and PVC Alternatives

When it comes to maintenance requirements, aluminum panels really shine compared to traditional options like wood and PVC. Wood looks great but needs constant attention to avoid rotting, bending out of shape, or getting eaten by insects. PVC might seem easy enough at first glance, but it doesn't handle extreme weather conditions quite as well as aluminum does. Aluminum stands up to whatever Mother Nature throws at it, lasting much longer without needing repainting, sealing, or all those costly treatments wood owners know too well. Plus, since aluminum isn't porous, it won't corrode or stain easily, so cleaning becomes a rare occurrence rather than a regular chore. What this means for building projects is simple math: fewer maintenance costs over time make aluminum panels a smart investment for structures that need to look good and last long without breaking the bank on upkeep.

In the modern construction landscape, aluminum panels provide a blend of economic efficiency, weight advantage, and maintenance simplicity, illustrating their utility and adaptability against traditional building materials.

FAQ

What are the benefits of using aluminum panels in construction? Aluminum panels offer several benefits including energy efficiency, aesthetic flexibility, sustainability, durability, cost-effectiveness, lightweight nature, and low maintenance.

How do aluminum panels contribute to energy efficiency? Aluminum panels enhance thermal insulation and help maintain internal temperatures, reducing the need for excess heating or cooling.

What makes aluminum panels a sustainable choice? Aluminum is highly recyclable and has eco-friendly manufacturing processes, positioning it as a leader in sustainable construction materials.

Are aluminum panels fire-resistant? Yes, aluminum panels often have fire-resistant cores, enhancing their safety ratings and compliance with building codes.