Key Properties of Aluminum Panels

Lightweight Design for Versatile Applications

Aluminum panels really shine when it comes to being light on weight. When we compare them to old school materials like steel or concrete, there's no contest - aluminum just weighs way less. And that makes all the difference during installation since workers don't have to struggle with heavy loads. The lighter weight actually saves money in multiple ways too. Shipping costs drop because these panels aren't so heavy, and buildings require fewer supports since they're not putting as much strain on the structure. Architects love working with them too because they can get creative with designs without worrying about weight limitations. We've seen some amazing modern buildings where the facade would have been impossible with heavier materials. For anyone looking at different options for their next project, lightweight aluminum panels offer something special that just plain works across many different types of construction.

Corrosion Resistance and Longevity

Aluminum panels resist corrosion pretty well because they develop this natural oxide layer on their surfaces. The layer acts as protection against damage from weather conditions, so these panels tend to stick around longer than many alternatives. Research indicates that in typical settings, aluminum panels often hold up for around 30 years before showing much wear and tear. That kind of durability makes them worth considering when looking at long term expenses. Since they don't require frequent maintenance checks or repairs, property owners save money over time. For both commercial buildings and homes where lasting materials matter, this characteristic becomes especially valuable. Because of how resistant they are to rust and decay, aluminum panels continue to be popular across various types of construction work.

Applications in Modern Construction

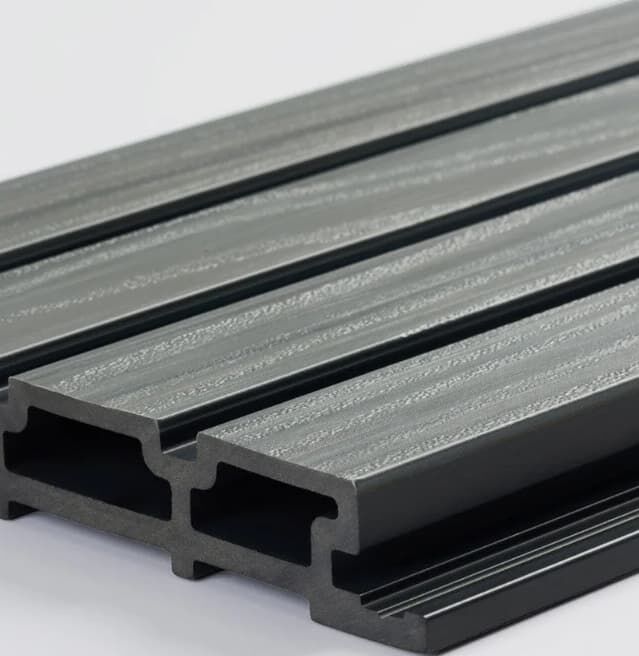

Facade Cladding and Ventilated Systems

Aluminum panels have become a go to material for facade cladding because they look good and work well together. Architects love working with them since they can create all sorts of different looks and textures that match what clients want. When used in ventilated facades, aluminum actually helps buildings save energy too. The natural airflow between the panel layers keeps interiors cooler in summer and warmer in winter without needing as much heating or cooling power. That's why we see these panels on everything from apartment complexes to office towers across the country. Plus, aluminum doesn't weigh much but holds up against weathering over time, resisting rust even in coastal areas where salt air would destroy other materials. This combination of looking great while standing up to real world conditions explains why so many builders specify aluminum for their projects.

Roofing Solutions for Industrial and Commercial Spaces

Aluminum panels are gaining popularity across industrial and commercial roofing projects because they're light yet tough enough to withstand harsh weather without cracking or warping. One big plus is how well they reflect sunlight, cutting down on heat buildup inside buildings. This means lower air conditioning bills for property owners who want to keep operating costs under control while still maintaining comfortable working conditions. Another major advantage comes from their lasting nature. Most buildings with aluminum roofs don't need repairs as often as those with traditional materials, saving money over time on maintenance crews and replacement parts. For business owners concerned about both building integrity and bottom line figures, aluminum represents a smart long term solution that works equally well whether installed on manufacturing plants in cold climates or retail centers facing intense summer sun.

Comparison: Aluminum Panels vs. Traditional Materials

Weight-to-Strength Ratio Advantages

Aluminum panels offer a great balance between weight and strength, making these materials really efficient when it comes to building different kinds of structures. Compared to old school stuff like concrete blocks and heavy duty steel, aluminum is much lighter but still holds up pretty well. That's why so many architects and contractors prefer working with aluminum nowadays. The fact that they're so light means we don't need as big foundations or complicated support systems, which cuts down on what the whole project costs. When builders aren't stuck dealing with super heavy materials, they get more freedom to experiment with creative designs that would otherwise be impossible because of weight restrictions. Plus, this approach opens up new ways to think about how buildings look while still saving money in the long run.

Maintenance Costs Over Time

Looking at maintenance expenses over time, aluminum panels actually beat out most traditional materials pretty handily. Most other materials need constant painting jobs or special treatments to fight corrosion, but aluminum just sits there resisting all sorts of weather conditions without much fuss. That means fewer trips back to the site for touch-ups and repairs, which cuts down on expenses quite a bit. For buildings standing decades, this makes all the difference between budget nightmares and reasonable upkeep. Studies have found some pretty impressive numbers too – around half the yearly maintenance bill compared to older materials when installed properly. Contractors who've switched to aluminum often mention not only saving money but also dealing with far fewer complaints from clients about fading colors or damaged surfaces after years of exposure.

Sustainability and Environmental Impact

Recyclability and Circular Economy Contributions

Aluminum panels can be recycled completely without losing their quality, making them great for the circular economy. Because of this, aluminum has become a go to material for people working on sustainable buildings. When we recycle aluminum instead of making new stuff from scratch, it takes just around 5 percent of the energy normally required. That makes a real difference for the environment. Using recycled aluminum helps manage waste better too. Many builders find that specifying recycled aluminum products appeals to clients who care about green building practices. The fact that aluminum stays usable forever means less trash ends up in landfills and we don't need so much raw material extracted from the earth. For these reasons, aluminum remains popular among architects looking to create eco friendly structures.

Reducing Carbon Footprint in Construction

The lightweight nature of aluminum panels helps cut down on carbon emissions in construction projects because they require less fuel to transport, resulting in a smaller carbon footprint overall. When properly installed, these panels actually reduce how much energy a building consumes once it's up and running. The EPA points out that structures built with materials like aluminum tend to emit fewer greenhouse gases over time. This fits right into current green building standards since aluminum naturally supports both lower emissions and better energy performance. As more companies focus on sustainability goals, the material advantages of aluminum are becoming increasingly important in modern construction practices.

Benefits Across Industries

Aesthetic Flexibility in Architectural Design

Aluminum panels bring real versatility to architectural work because they can be shaped, sized, and finished in so many different ways during fabrication. Architects love this flexibility since it lets them create buildings that stand out from the crowd. The material comes in countless colors and textures too, so designers can match almost any aesthetic requirement while still getting something tough enough to last. When specifiers choose aluminum for facades or interior elements, the building just looks better overall, which matters a lot when presenting proposals to clients or attracting people who will actually use the space. That's why we see aluminum showing up everywhere these days in projects that want to look contemporary and cutting edge, or need some seriously creative solutions for complex spaces.

Fire Resistance and Safety Compliance

Aluminum panels don't burn, which makes them a go to option when it comes to improving how buildings resist fires. This feature matters a lot for meeting those tough building safety regulations, especially important in tall buildings across cities where code compliance just cannot be ignored. The way aluminum looks after finishing also helps boost fire rating numbers, something that cuts down on potential legal problems for anyone involved in construction projects. Construction professionals regularly push for using aluminum materials in areas prone to fire risks because they know these materials actually work at reducing dangers and keeping people safe inside buildings. When architects pick aluminum panels, they get both safety benefits and maintain good aesthetic quality in their designs without having to sacrifice either aspect.

FAQ

Why are aluminum panels considered lightweight?

Aluminum panels are lighter than traditional materials like steel or concrete, making them easy to handle and install, which reduces shipping and structural support costs.

How long do aluminum panels last compared to other materials?

They can last over 30 years without significant degradation due to their corrosion-resistant properties, requiring less maintenance and lowering costs over time.

Are aluminum panels suitable for roofing?

Yes, they are preferred for their durability, resilience to weather, and reflective properties which help minimize heat absorption, reducing cooling costs.

Can aluminum panels be recycled?

Absolutely, aluminum panels are 100% recyclable without loss of quality, supporting circular economy principles and reducing environmental impact.

Do aluminum panels have good fire resistance?

They are non-combustible, enhancing fire resistance in buildings and meeting stringent safety codes, especially in urban high-rise settings.