pvc shower wall panel manufacturer

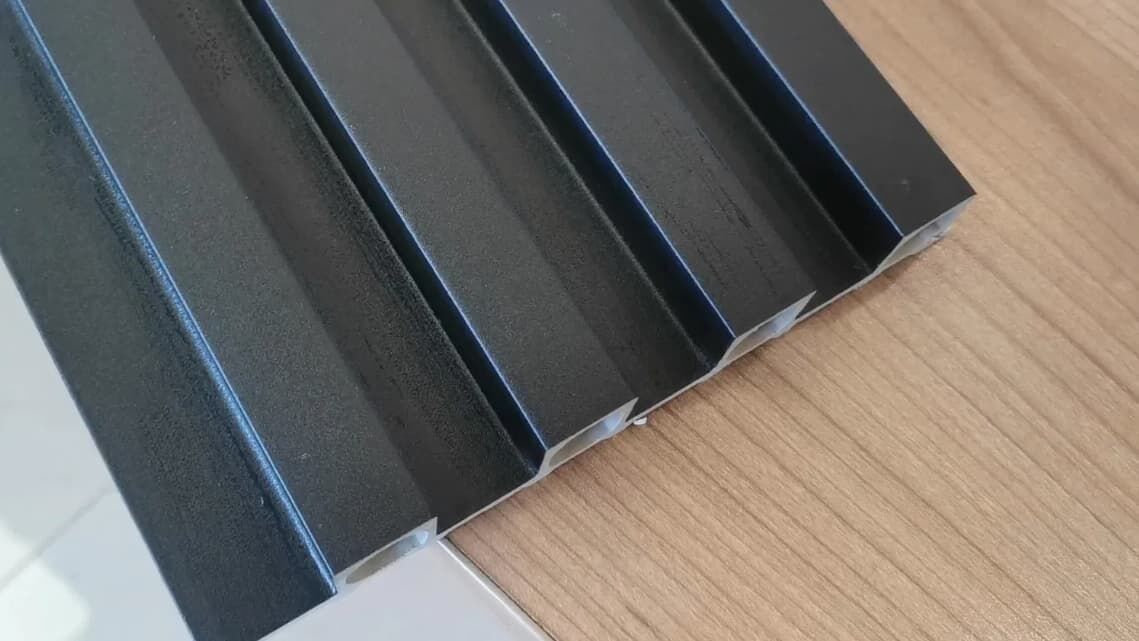

A PVC shower wall panel manufacturer specializes in producing high-quality, waterproof wall solutions for modern bathrooms. These manufacturers employ advanced manufacturing processes and state-of-the-art equipment to create durable, aesthetically pleasing panels that serve as an alternative to traditional tiling. The production facility typically features automated production lines that ensure precise cutting, molding, and finishing of PVC panels to exact specifications. The manufacturing process involves the use of virgin PVC materials combined with specialized additives to enhance durability, UV resistance, and color stability. These facilities maintain strict quality control measures throughout the production cycle, from raw material selection to final product inspection. The manufacturer's capabilities often include custom design options, allowing for various patterns, textures, and colors to meet diverse customer preferences. The production setup incorporates modern extrusion technology that ensures consistent panel thickness and smooth surface finish. Additionally, the facility typically houses advanced printing and coating equipment to apply decorative finishes that mimic natural materials like marble, stone, or wood. The manufacturer also emphasizes environmental responsibility by implementing waste reduction strategies and recycling programs in their production process.